By Boo Chanco (DEMAND AND SUPPLY) | The Philippine Star | November 5, 2014

It had been a while since the private owners of MRT 3 commissioned MTR HK to conduct a study on the true state of the system. The study had long been pushed off by DOTC and I suppose they finally agreed to do it only after a series of almost daily accidents happened.

Even then, my sources told me DOTC hardly cooperated with MTR HK. During the time of the former MRT 3 GM, the experts from MTR HK ended up going home empty handed as they were not given access to MRT 3 trains and depot.

This time around, the reluctance to cooperate is still there. I was told that DOTC hardly gave MTR HK any documents to work with – just one year of Sumitomo’s record, only one month of APT Global and none whatsoever of PH Trams records. MTR HK has had to depend on the limited visual inspection they were allowed.

With the limitations, the MTR HK report, which is yet to be officially released, basically says the maintenance work being done on MRT 3 is unsatisfactory and/or sloppy. Also that there is an overall lack of spares and various important equipment that are not working.

Here are portions of the Executive Summary which confirm our worst fears:

Asset Performance: Asset performance review was conducted based on the performance figure made available from Metro Rail Transit Corporation, Global APT JV and Sumitomo Corporation covering one monthly maintenance report (5 Jun to 4 Jul 2014) and 13 Vehicle & System’s Report for Three Weeks (13 Oct 2011 to 12 Sep 2012), interview with relevant stakeholders, and assessment during site visits.

Business

The overall performance is unsatisfactory. It is believed that the unsatisfactory asset performance was very likely related to the inappropriate maintenance interval and maintenance content. It is expected that the train performance will further deteriorate in coming years if reliability improvement works and proactive maintenance works are not implemented on the train fleet as well as depot plants.

To achieve better train performance, it is advised to make use of the data collected and perform Failure Mode, Effects and Criticality Analysis (FMECA) in monthly reports to identify the root cause and resolve the defects for critical systems including traction motor, door systems and air conditioning unit.

It is also suggested to reduce the preventive maintenance intervals and restore all stopped cars in the depot as soon as reasonably practicable. Besides, mid-life/end of asset life refurbishment should also be performed for car-body structure, ATP system, Bogie and Door systems, in addition to the development and implementation of asset management plan with regular asset condition review.

Asset Condition: The physical conditions of the train fleet have been assessed by random sampling. The train units selected for assessment were Train Unit 028 and Train Unit 024, with each train unit formed by Car A, Car B and Car C.

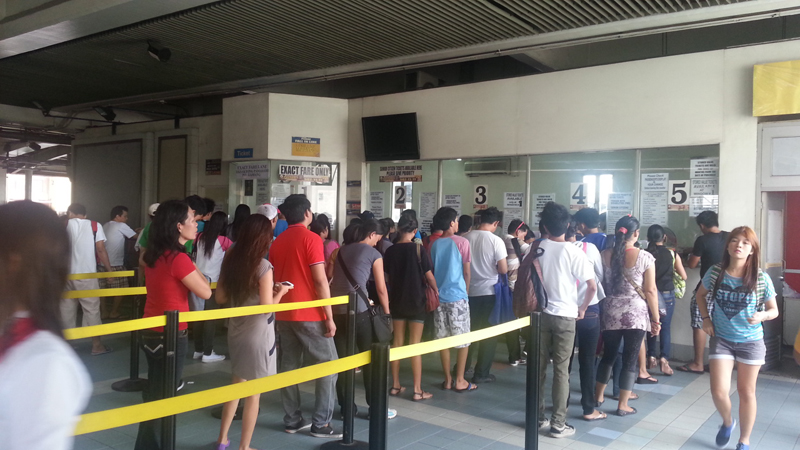

The outcome of the assessment is considered unsatisfactory. With the increasing running mileage due to the strengthened operations to three minutes headway and 18 hours operation per day, and the growth of passenger capacity per day from 360,000 as per design to the actual capacity of up to 540,000 in 2014, the asset conditions for those critical systems would worsen due to heavier duty in the future and more severe operating environment than the original design.

Asset condition capability assessment should be carried out every three years so as to continuously monitor the asset condition and its performance. Maintenance content and regime shall also be reviewed every three years so as to have an efficient and appropriate maintenance arrangement based on the asset condition at that point.

Since the assets have been in service for 14 years, and is reaching the middle of the 30 years design asset life, mid-life refurbishment or one-off replacement should be performed.

Asset Capability: The capability of the train is hindered by several limitations such as the signaling systems, the platform capacity and the interfacing capacity on train.

Reliability Performance Trend – Today the daily passenger and mileage run in MRT3 has far exceeded its designed capacity. The heavier passenger loading and higher operational frequency of the train assets has naturally led to a reduction in the designed asset life.

For example, due to heavier loading, the increase in torque demand will place considerable stress on the traction motor, which will directly shorten its life time and affect the reliability and availability of the train.

It is deemed necessary that an asset maintenance plan be developed in addition to the regular maintenance tasks. Hard-time replacement regime and component refurbishment regime (e.g. traction motor refurbishment) shall be developed such that some assets will not be left to operate for a long time without being properly maintained.

A proactive asset maintenance plan will help to ensure the performance until it reached the end of its asset life.

Train availability – As indicated in the Monthly Maintenance Report provided by GLOBAL-APT, the DOTC vehicle availability requirement during peak hours cannot be met on several dates. Meanwhile, there were five stopped cars stabled in the depot waiting for maintenance activities to be carried out.

If these vehicles can be used as standby to replace other faulty trains, that will reverse the declining trend of the reliability performance. It is therefore highly recommended to restore these five stopped cars as soon as reasonably practicable in order to fulfill the train availability requirement.

Besides, the total mileage run for the whole fleet has dropped by 6,197 km from May to June 2014. As the train availability will affect the total mileage run, a thorough root cause analysis should be performed to investigate the reasons of train withdrawal from service in order to improve train availability.

From the Vehicle & System’s Report for Three Weeks, there were altogether 1,130 vehicle defects from 13 Oct 2011 to 12 Sep 2012 (with missing information from three periods: 08/03/12 to 28/03/12, 10/05/12 to 30/05/12, and 21/06/12 to 11/07/12).

Among all the vehicle defects, 413 are major defects and 717 minor defects. A major defect is defined as train becoming out of service / removed during peak hour and minor defect is defined as reported defects at mainline with minor rectification / repair at the depot. The top 3 dominating causes of defects are related to: traction system (32 percent), doors (nine percent) and train-borne signaling system (eight percent).

In addition, there were a total of 189 Removal Defects identified from 5 Jun 2014 to 4 Jul 2014 in MRT3 rolling stock. The top 3 major removal defects including: Train-borne Signaling system failures (22 percent); Traction System failures (14 percent), and Passenger Air Conditioning Unit failures (12 percent)...

Preventive Maintenance planning – It is observed that MRT3 and MTR have similar service hours and peak loading, however the maintenance interval of trains in MRT3 is longer than that in MTR. It is suggested that MRT3 review the preventive maintenance interval.

46 traction motors were replaced from 5 Jun 2014 to 4 Jul 2014. It is suggested to have a well-planned preventive maintenance regime to lower the replacement rate. An in-depth investigation shall also be carried out on the frequent traction motor failures.

In the coming three years, it is anticipated that the performance of the trains will continue deteriorate as some of the major systems or components will reach its end of asset life or mid-life, e.g., car-body structure, ATP system, Bogie and Door systems.

A comprehensive asset management plan and a regular asset condition review for LRV and major depot plants have to be developed and timely implemented to maintain and monitor the asset performance. Asset life extension study for the train fleet is suggested to be carried out 3-5 years before the end of its asset life.

There are more details in the Executive Summary than we have space in this column. Suffice it to say that there is a lot of work to be done and I wonder if DOTC is up to the job. I still think the private sector should be allowed to rehabilitate the MRT 3 system for the safety of the public. Based on what we have seen now, it is clear DOTC just cannot be trusted with the responsibility.

Twitter

Twitter Facebook

Facebook